A globe valve is a linear-motion valve type that provides precise flow rate adjustment and high sealing performance in fluid lines. In this comprehensive guide, we explain all critical aspects—from definition and operating principle to types, selection criteria, and application areas—in clear but technically accurate language. Use the checklist at the end to clarify your project, and contact us now for expert support and a fast quotation.

Selecting the right globe valve is not only a hardware decision—it is a control strategy decision that impacts pressure management, energy consumption, and long-term reliability across the entire line. When the valve is correctly specified (type, trim, materials, and actuator), you reduce unplanned downtime, stabilise setpoints, and protect downstream equipment from excessive differential pressure, noise, and premature wear. If you share your operating conditions, our team can quickly validate sizing (Kv/Cv), recommend the most suitable body style and trim, and align leakage class and standards with your project specification—so you procure with confidence and avoid costly rework.

What is a Globe Valve? Definition and Main Components

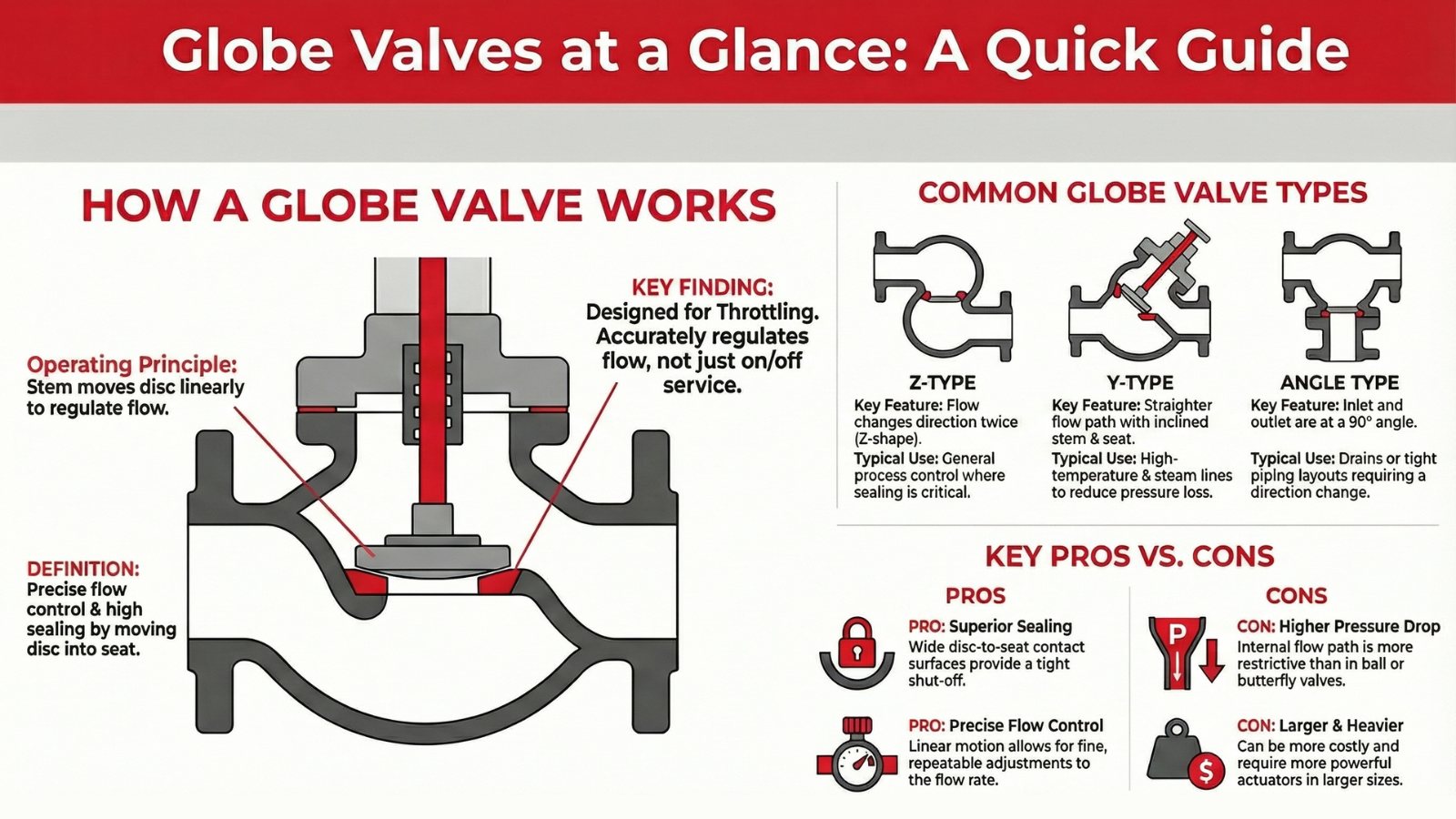

A globe valve is a control element consisting of a body, bonnet, stem, disc (plug) and seat. By means of the disc–seat contact surface, it throttles or shuts off the flow. Thanks to its linear motion, position repeatability is high and it delivers precise results even with small adjustments. This characteristic makes it a reliable solution both for process control and for shut-off duty.

Inside the valve body, the flow changes direction in the disc and seat area. This geometry can cause a higher pressure drop compared with butterfly or ball valves; in return, throttling performance and sealing quality are improved. With the correct choice of materials, surface roughness and torque management, a long service life and stable operation are achieved.

Disc, Seat and Stem: The Heart of Sealing

The shape of the disc (flat, plug/needle type) and the machined surface of the seat are the main factors determining the leakage class. The up-and-down motion of the stem is designed to minimise fugitive emissions in the packing area; graphite- or PTFE-based materials are selected according to temperature and fluid properties.

Flow Characteristic and Kv/Cv (conceptual)

A globe valve can provide a linear or equal-percentage-like control characteristic. The correct combination of valve size and disc geometry ensures gradual, predictable changes in flow rate, which improves stability in PID-controlled processes.

Operating principle: linear motion and flow control

A globe valve operates by moving the stem in a straight line with a handwheel or actuator. As the disc moves away from the seat, the flow increases; as it approaches, the flow decreases. The surface finish at the disc–seat contact ensures repeatable behaviour even for small stroke changes, allowing you to reach the desired flow quickly and reliably. This behaviour supports stable flow control even when temperature or viscosity conditions change.

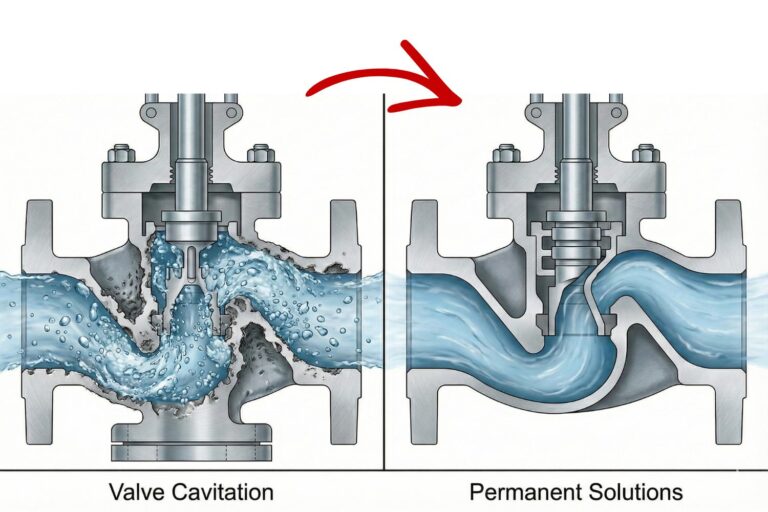

In throttling service, the acceleration zones and pressure differences along the disc edge must be managed carefully. A suitable operating range reduces the risk of cavitation and erosion. For this reason, when sizing the valve, the expected operating percentage, line pressure and backpressure are evaluated together.

Flow direction and pressure effects

In most designs, flow direction is selected to optimise the forces acting on the disc and packing. “Flow under the disc” or “flow over the disc” configurations affect closing torque, vibration behaviour and packing life.

Throttling and cavitation management

In throttling applications, the pressure drop should be distributed in a controlled way. Where necessary, multi-stage trims or anti-cavitation designs should be considered. This approach limits erosion and noise while preserving seat integrity.

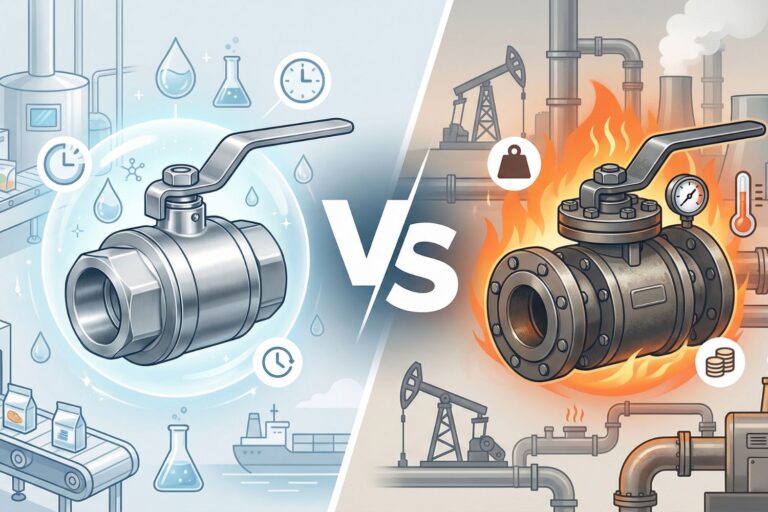

Globe Valve Types and Designs

Globe valves differ according to internal flow path and ease of maintenance. When selecting a design, you should consider piping layout, accessibility, pressure drop and maintenance strategy. Disc and seat materials are tailored to process requirements with soft-seated or metal-to-metal combinations.

In lines exposed to thermal cycling over time, bonnet tightness, bolt preload and gasket type become critical. Correct tightening torques and re-tightening procedures simplify long-term emission control.

Z-type, Y-type and angle type: results of design differences

Z-type bodies are a common choice due to their high sealing performance and easy maintenance; Y-type bodies offer reduced pressure loss and advantages at high temperatures. Angle designs provide compact piping solutions where a 90° change of direction is required and simplify drainage and blow-down.

Comparative table: globe valve types and typical uses

| Type | Flow path / Feature | Pressure drop | Typical size (DN) | Typical use | Key advantage |

|---|---|---|---|---|---|

| Z-type | Flow changes direction twice | High | 15–300 | General process, on/off and control | Sealing stability |

| Y-type | Straighter flow; inclined body | Medium | 15–250 | High temperature, steam lines | Lower pressure drop |

| Angle type | 90° turn; easy drainage | Medium | 15–200 | Condensate, drain, tight spaces | Compact piping arrangement |

Advantages: Sealing, Precision, Serviceability

Thanks to the wide disc–seat contact surfaces and machined seating geometry, a globe valve offers high sealing performance. Linear motion allows fine adjustment even with small stroke changes, reducing process fluctuations and contributing to product quality consistency. In addition, packing adjustment and top-entry designs shorten maintenance time.

During service, the disc and seat surfaces can be re-machined or replaced. This reduces total cost of ownership. Combined with an appropriate actuator, the valve delivers fast response, low overshoot and energy-efficient control.

Disadvantages and Proper Use Cases

Because of its internal geometry, a globe valve creates more pressure loss than butterfly or ball valves. In larger sizes, cost and required actuation torque increase. Therefore, for large-diameter lines in simple on/off service, alternative valve types may be more economical; however, in lines requiring accurate modulation, the control valve function of the globe valve usually provides superior performance.

For fluids containing abrasive particles, disc and seat surfaces must be protected with special coatings. If material pairing is not optimised, erosion accelerates and the leakage class may deteriorate. These risks are managed through the right material, coating and operating range.

Selection Criteria: Material, Connection, Standards

The first step in selection is the pressure–temperature envelope and the chemical/physical properties of the fluid. Carbon steel, stainless steel or alloy steels are chosen according to temperature, corrosion, hydrogen influence and similar factors. Surface roughness and hardness directly affect the durability of the required leakage class.

Standard compliance is ensured through dimensional classes, material certificates and tightness tests. Depending on the project specification, ASME/ANSI, EN/ISO and API requirements are evaluated. Test plans and traceability documentation speed up commissioning.

Connection and Actuation Options

Flanged, threaded (NPT), socket-weld (SW) or butt-weld (BW) ends are selected according to your installation and maintenance strategy. On the actuation side, manual handwheel, electric/pneumatic actuators and positioners allow precise modulation.

Leakage classes and test philosophy

The required leakage class is determined by process risk. Metal-to-metal trims are preferred at high temperatures, while soft-seated designs provide low torque and higher tightness. Hydrostatic and pneumatic tests verify body and seat leakage.

Application areas: power, process, infrastructure

In power plants, globe valves are used in steam lines, condensate collection and auxiliary services to provide a safe balance of throttling and shut-off. In chemical and petrochemical facilities, they improve process efficiency by precise flow control on reactor feeds, heat exchanger inlets and pressure-reducing lines.

In infrastructure and HVAC, they are used for balancing and equipment protection in hot/chilled water circuits. In seawater and mildly corrosive services, suitable material and coatings extend service life. In all cases, proper support against vibration and thermal movement of the line is essential for performance.

Pre-purchase globe valve checklist

- Process data: are minimum/normal/maximum flow, pressure and temperature ranges clearly defined?

- Fluid properties: have viscosity, particle content and corrosion/cavitation risks been evaluated?

- Body/disc/seat materials: are they fully compatible with the fluid and temperature?

- End connections and installation conditions: flange standard, welding procedure and accessibility confirmed?

- Actuation/automation: are actuator torque, positioner and feedback requirements clearly specified?

- Leakage class and test plan: are acceptance criteria and reporting scope written into the specification?

- Maintenance strategy: are spare parts, packing materials and service accessibility planned?

Maintenance, safety and documentation

In planned maintenance, packing adjustment and visual inspection of sealing surfaces are essential. Torque values must be applied according to manufacturer recommendations, and stem straightness as well as guide surfaces should be monitored for wear. Proper lubrication and correct stroke limits extend actuator life.

Traceability codes on the equipment, material certificates and test reports simplify audits and warranty processes. EMS Valve engineers define commissioning and maintenance procedures on a project-specific basis, helping you reach your emission and safety targets quickly.

Conclusion and next step

A globe valve combines precise flow control, high sealing performance and good serviceability, making it a robust and reliable solution wherever both throttling and shut-off are required. By selecting the right type, material and actuation according to your project data, you can achieve an optimal balance of performance and cost. Get in touch now so we can evaluate your globe valve requirements and provide a fast, tailored quotation.

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.