Fundamental Differences Between Gate Valves and Globe Valves: A Comprehensive Comparison

In industrial plants, valve selection is a critical engineering decision in terms of process safety, accuracy, and operational efficiency. Gate valves and globe valves are two common linear-motion valve types that may look similar from the outside, but their internal geometry and primary functions are fundamentally different. An incorrect valve selection can lead to energy losses and serious system failures.

This article examines the key mechanical, hydraulic, and operational differences between gate valves and globe valves and sets out practical selection criteria.

Basic Function and Operating Principle

The most important distinction between the two valve types lies in their core function: isolation (shut-off) versus flow regulation (throttling).

| Feature Category | Gate Valve (Sürgülü Vana) | Globe Valve (Glob Vana / Stop Valve) |

| Primary Function | Isolation (Fully Open/Fully Closed) | Flow Regulation (Throttling), Isolation |

| Throttling Capability | Poor, High Risk of Damage | Excellent, Precise Control |

Purpose of a Gate Valve: Isolation

A gate valve is designed to fully open or fully shut off the flow of liquids or gases. The gate (disc/wedge) inside the valve moves in a vertical plane perpendicular to the flow direction, either completely blocking the passage or providing full bore flow.

Operating condition: Gate valves are recommended to be operated only in fully open or fully closed positions.

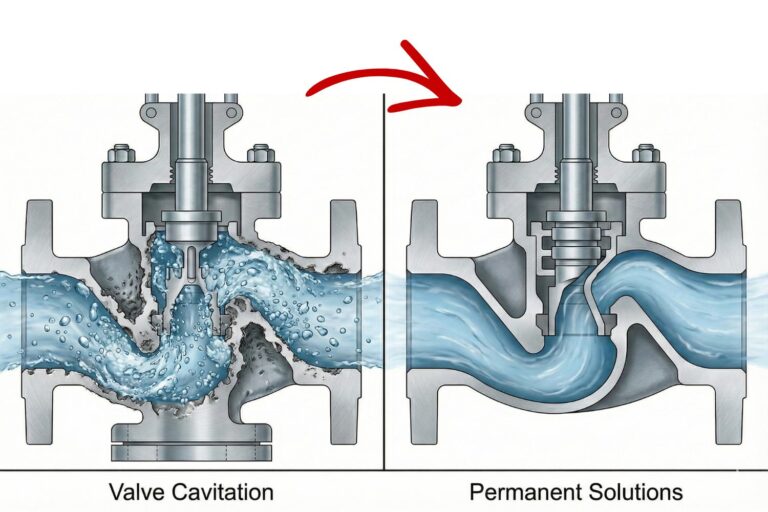

Throttling risk: Using a gate valve in a partially open position causes vibration and erosion on the sealing surfaces, significantly shortening its service life and damaging the seat and disc.

Purpose of a Globe Valve: Control and Regulation

A globe valve (also referred to as a stop valve) is designed to start, stop and, more importantly, precisely control the flow rate. A globe valve acts as a control valve that can modulate the flow according to the opening percentage.

Operating mechanism: In a globe valve, there is a disk and a seat on the flow path. The conical plug moves vertically towards the seat, and this motion adjusts the flow gradually.

Flow Dynamics and Pressure Drop Comparison

The fundamental hydraulic difference between these two valve types is the resistance encountered by the fluid as it passes through the valve. This resistance directly affects the system’s energy efficiency.

Gate Valve: Low Pressure Drop

When the gate in a gate valve is fully retracted, it creates a straight-through, full-bore flow path. There is no reduction in internal diameter along the line.

Flow resistance: When the valve is fully open, the resistance applied to the fluid is almost zero.

Energy efficiency: The pressure drop (ΔP) is minimized. This is a major advantage for high-flow and long-distance pipelines in terms of energy efficiency.

Globe Valve: High Pressure Drop

The internal geometry of a globe valve forces the fluid to change direction as it flows through the valve; the fluid must flow around the disc.

Flow resistance: This enforced change in direction creates high flow resistance.

Pressure drop: The pressure drop across a globe valve is significantly higher than that of a gate valve. This high resistance is a structural feature that enables effective throttling performance. However, where no control is required, it can substantially increase energy consumption.

Mechanical Design and Operational Differences

Operating Speed and Torque Requirement

Gate valves and globe valves differ in opening/closing speed and required operating torque:

Gate valve:

- Torque: Requires relatively low external force; it operates with lower torque.

- Speed: The stroke of the gate along the vertical axis is quite long, which results in a longer opening and closing time.

Globe valve:

- Torque: Must overcome higher flow resistance due to its internal geometry; therefore, it requires higher effort and higher torque for opening and closing.

- Speed: The stroke of the disc is much shorter, so opening and closing are faster compared to a gate valve.

Installation Direction and Flow Direction Limitation

The most important difference during installation is the restriction on flow direction.

Gate valve: Since the resistance to flow is the same in both directions, a gate valve is bidirectional. There is no requirement for inlet and outlet orientation.

Globe valve: The flow direction is strictly limited and essentially unidirectional. During installation, the arrow on the valve body indicating the flow direction must be followed precisely.

Size and Maintenance

The structural design of gate valves and globe valves affects their installation and maintenance characteristics:

Vertical height: The overall height and opening height of a gate valve are relatively large due to the rising stem, and therefore require more vertical space.

Face-to-face length (horizontal dimension): Gate valves generally have a shorter face-to-face dimension than globe valves. Globe valves can be longer in the horizontal direction due to their more complex internal flow path.

Sealing performance: Globe valves typically provide better tight shut-off and longer sealing life than gate valves. Gate valves usually have two seating surfaces, which makes machining, lapping and repair more difficult.

Application Areas and Selection Criteria

Valve selection should be made strategically based on the system’s flow control requirements and nominal diameter (DN).

Typical Applications for Gate Valves

Gate valves are the most suitable option in systems where the fluid is only required to be fully opened or fully shut off.

Reasons for preference: Low pressure drop, energy efficiency, and bidirectional flow capability.

Common applications: Water distribution systems, sewer networks, fire protection lines, oil and gas transmission pipelines, power plants, and high-flow industrial pipelines.

Size threshold: They are generally preferred as shut-off / isolation valves on lines with nominal diameters greater than DN50.

Typical Applications for Globe Valves

Globe valves stand out in lines where the flow rate must be continuously or frequently controlled.

Reasons for preference: Precise flow control (proportional control) and reliable unidirectional tightness.

Common applications: Chemical plants, laboratory systems, central heating and cooling circuits (HVAC), steam and feedwater lines, and similar process control applications where continuous adjustment is required.

Size threshold: They are generally used in systems with nominal diameters smaller than DN50, because at larger diameters the high torque and energy loss become operationally unacceptable.

Summary Comparison Matrix (Technical Focus)

| Feature Category | Gate Valve (Sürgülü Vana) | Globe Valve (Glob Vana / Stop Valve) |

| Flow Path Geometry | Straight, Full Bore | Curved, Flow Direction Change |

| Pressure Drop ( ΔP ) | Very Low (Near Zero) | High (Due to structural resistance) |

| Installation Direction | Bi-Directional, No direction restriction | Uni-Directional, Must follow arrow sign |

| Operating Torque | Low (Smaller actuator) | High (Larger actuator) |

| Opening/Closing Stroke | Large/Long (Slow) | Small/Short (Fast) |

| Sealing Mechanism | Friction and Sliding | Vertical Compression (Squeezing) |

| Typical Application Dia. | Large Diameters (DN50+) | Small Diameters (DN50-) |

Strategic Engineering Advice:

When selecting a valve, if precise flow adjustment is mandatory, a Globe Valve must be chosen, despite the accompanying high energy loss cost. However, if only opening/closing is required, choosing the Gate Valve due to its low fluid resistance and energy efficiency will dramatically reduce the plant’s long-term operational costs (OPEX). Using a gate valve for throttling is an error that must be avoided, as it leads to rapid wear of valve components and early failure.

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.