In the pipeline systems that function as the heart of industrial facilities, safety and sustainability come first. Especially in processes involving high pressure, high temperatures, or corrosive fluids, the durability of the valve body is vital. The question engineers and procurement specialists frequently ask, “Cast valve or Forged steel valve?”, is actually a critical decision that determines the lifespan of the facility.

With over 40 years of manufacturing experience, EMS Vana presents this guide to ensure you don’t leave your industrial safety to chance. We delve into the details of forged technology, Class 800 standards, and metallurgical advantages. Are you ready to make the right decision for your project?

What is a Forged Valve? The Manufacturing Difference

A Forged Valve is a highly durable flow control component produced by heating metal and shaping it under high pressure using mechanical forces. Unlike the casting method, metal is not melted and poured into a mold; instead, solid-state metal is compressed and formed into the desired shape.

During this process, the grain structure of the material aligns with the shape of the valve. This alignment significantly increases the valve’s impact resistance, tensile strength, and fatigue life. The term “Forged valve body”, frequently encountered in search engines, refers to this superior structural integrity.

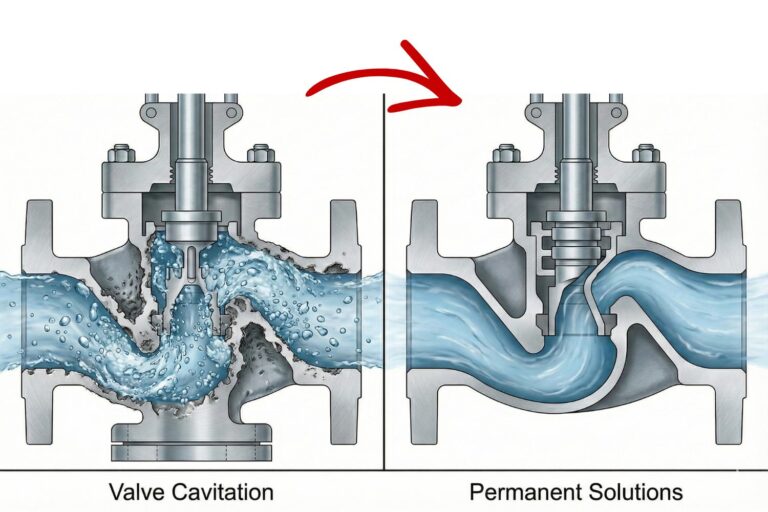

Why Forged Over Cast?

Cast Valves are produced by pouring molten metal into molds. While this method offers cost advantages for large-bore valves, it harbors microscopic risks:

- Porosity: Air bubbles trapped during casting can create voids within the body.

- Shrinkage: Volumetric contraction as the metal cools can create weak points in the internal structure.

In forged steel valves, the risk of porosity or internal voids is near zero. The material, compressed under high pressure, achieves a perfectly homogeneous structure. For this reason, forged valves are mandatory for “critical lines” in refineries and power plants.

Insurance for High Pressures: Class 800 and Class 1500 Standards

Terms like Class 800 ball valve or Gate valve Class 800, often seen in Google searches, point to the most common application range of forged valves. Forged steel valves are typically used in small-bore lines (1/2″ – 2″) requiring high-pressure resistance.

While cast valves are common in Class 150 and Class 300 (PN16 – PN40) ranges, forged valves are the standard for the following pressure classes:

- Class 800: The industrial standard for forged valves. Resistant up to approximately 138 bar pressure.

- Class 1500 & Class 2500: Manufactured for ultra-high pressure steam lines and hydraulic systems.

If your project involves pressures above 50 bar or carries a risk of thermal shock (sudden temperature changes), using a cast valve is a significant risk factor.

The Gold Standard in Material Quality: ASTM A105 and A182

Ideally, a valve being “Forged” is not enough on its own; the raw material quality defines the performance. As EMS Vana, we ensure full compliance with international standards (ASME/ASTM) in our production.

1. Carbon Steel (ASTM A105)

This is the most preferred forged material grade in the industry. The high search volume for “A105 valve” proves its popularity. It performs perfectly in water, steam, oil, and gas lines between -29°C and +425°C.

2. Alloy Steel (ASTM A182 F11 / F22)

Used in power plant applications requiring high-temperature creep resistance (above 500°C). Thanks to Chromium and Molybdenum alloys, it maintains its form even under extreme heat.

3. Stainless Steel (ASTM A182 F304 / F316)

Preferred in chemical plants and food lines where corrosion is the main threat.

Applications and Advantages of Forged Steel Valves

Forging technology offers not only durability but also versatile installation options. Forged valves are typically manufactured with Socket Weld (SW) or Threaded (NPT) connection types, ensuring easy and secure installation in lines where leakage prevention is critical.

Key Application Areas:

- Refinery & Petrochemical: Control of flammable and explosive fluids.

- Natural Gas Pipelines: High-pressure transmission lines.

- Power Plants: High-pressure superheated steam lines (Forged Globe Valves).

- Hydraulic Systems: Lines subject to sudden pressure surges (Water Hammer).

Table: Cast vs. Forged Valve Comparison

The table below clearly summarizes why you should choose a forged valve for your project:

| Feature | Forged Steel Valve | Cast Steel Valve |

| Internal Structure | Homogeneous, non-porous, tight grain structure | Risk of porosity and sand inclusion |

| Pressure Class | High Pressure (Class 800 – 4500) | Medium/Low Pressure (Class 150 – 600) |

| Impact Resistance | Excellent toughness and fatigue resistance | Brittle structure, lower impact resistance |

| Material Defects | Near zero (Compressed via mechanical force) | Internal voids and shrinkage may occur |

| Wall Thickness | Higher strength with thinner walls | Requires thicker walls for same rating |

| Weldability | Excellent (Due to homogeneous structure) | Can vary; requires care |

| Cost | Higher initial investment, economical operation | Lower initial investment |

EMS Vana: Turkey’s Forged Valve Manufacturing Base

Producing with “Domestic Production” power at global standards (API, ASME, ISO), EMS Vana offers a wide product range in the forged steel valve category. Our Forged Gate, Forged Globe, and Forged Check valves take their place in the field after passing the most rigorous tests.

“Tests and inspections, acceptance tests, and pressure tests are performed according to API 6D, API 598, or Customer standards. Visual, dimensional control, and chemical composition analyses are meticulously carried out in our ISO 17025 accredited laboratory.”

Unlike competitors, EMS Vana is not just an assembler but a manufacturer managing every stage from raw material to the final product. This allows us to combine our local strength with global quality expectations like Forged Valve requirements.

Conclusion: You Cannot Compromise on Safety

In industrial facilities, the cost of unplanned downtime is far higher than the cost of a valve. Micro-cracks and leakages that cast valves may develop under high pressure threaten both personnel safety and production continuity.

For pressure classes of Class 800 and above, Forged Steel Valves are not a preference but an engineering necessity. Maximize your facility’s safety with our 100% domestically produced, certified, and guaranteed forged valve solutions.

Contact our expert engineering team for valve selection suitable for your project’s specific pressure and temperature values.

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.