Valve solutions play a critical role in safety, continuity and efficiency across oil & gas, power and chemical facilities. This guide provides practical, applicable insights to help you select the right valve type, material and sealing design for each industry. Take notes on your project data as you read; at the end, align them with the checklist and request a quotation immediately.

Valve solutions: overview of sector-specific requirements

In oil & gas, “high pressure, H₂S/CO₂ exposure and ESD safety” are key drivers. In power generation, “high temperature in the steam cycle and cavitation management” are decisive. In chemicals, “corrosive media, solvents and emission limits” shape the selection criteria. In all three, valve solutions are based on the correct combination of standards (ASME/ANSI, API, EN/DIN), materials and actuators.

Valve solutions for oil & gas applications

Summary objective: Maximum process safety, low fugitive emissions and operational continuity.

Typical lines: Wellhead/flowline, gathering–separation, transfer lines, manifolds, storage–loading.

Upstream: production and separation lines

Recommended types: Thru-conduit gate valves, trunnion ball valves, choke/plug valves, dual plate check valves.

Rationale: Full bore, low pressure drop, fast shut-off and tolerance to solid particles.

Materials & compliance: Sour-service compliant alloys, NACE/MR compliance; metal-to-metal or soft-seated designs are selected based on the process fluid.

Midstream: pipelines and stations

Recommended types: API 6D trunnion ball valves, slab/expanding gate valves, swing/dual-plate check valves, emergency shutdown (ESD) valves.

Notes: Pigging compatibility, low operating torque and low-emission stem and body sealing (targeting ISO 15848, API 641).

Downstream & LNG/LPG: refineries and terminals

Recommended types: Trunnion ball valves for high-cycle lines; globe valves for throttling; silent check valves for backflow protection.

Materials: Austenitic stainless steels for cryogenic lines; PTFE/graphite-based gasket configurations in sealing areas.

Valve solutions for power plants

Summary objective: Shape stability at high temperature, throttling performance and cavitation/noise control.

Steam cycle and auxiliary lines

Recommended types: Globe valves (throttling/droplet control), gate valves (main line isolation), check valves (pump protection) and high-performance butterfly valves in larger diameters.

Application examples: Boiler feedwater regulation, bypass lines, attemperation lines, condensate discharge.

Materials: High-temperature alloys (e.g. Cr–Mo steels), metal-to-metal seating and graphite gaskets.

Cooling water and auxiliary fluids

Recommended types: Butterfly valves and check valves; corrosion-resistant bodies/shafts with suitable coatings.

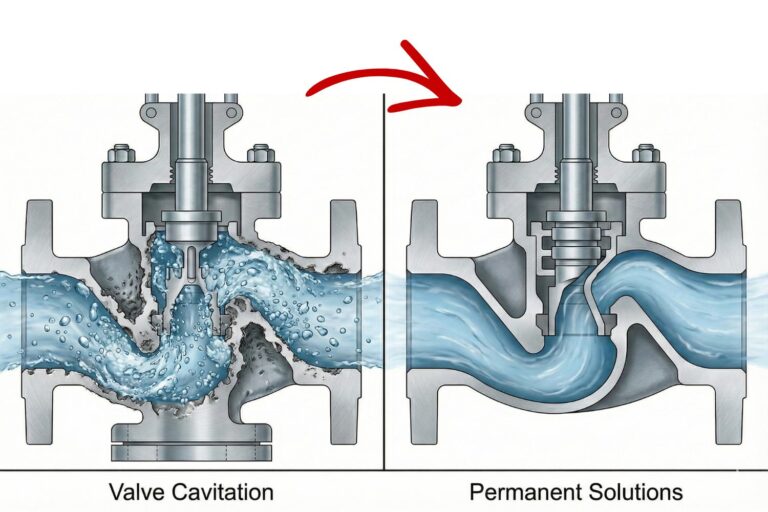

Notes: For cavitation risk, multi-stage trims or special disc geometries are preferred.

Valve solutions for chemical and petrochemical processes

Summary objective: Chemical resistance, tightness class and emission control (alignment with LDAR programmes).

Corrosive and solvent-based environments

Recommended types: Plug/ball valves (low torque and full bore), globe valves (precise throttling), diaphragm valves (abrasive/cleanable lines).

Materials/linings: Stainless steels, superalloys, PTFE/PFA linings; soft-seated designs with low-leakage focus.

Hygienic applications & process safety

Applications: CIP/SIP lines, reactor feed/discharge, heat exchanger inlets.

Rationale: Smooth wetted surfaces, easy maintenance and traceability; support for validation and documentation.

Selection criteria: checklist for the right valve solutions

The checklist below helps reduce unnecessary revisions and downtime at project start:

- Process envelope: Pressure–temperature, min/nominal/max flow, viscosity.

- Fluid chemistry: H₂S/CO₂, particles, polymerisation risk, corrosion data.

- Function: Isolation/throttling/one-way control/ESD; required tightness class.

- Connection and size: Flange standard (ASME/EN), BW/SW/NPT; pigging compatibility (oil & gas).

- Actuation: Manual, pneumatic, electric; positioner/feedback, SIL/ATEX requirements.

- Standards and testing: ASME/ANSI, API, EN/DIN; hydrostatic/pneumatic tests, emission tests.

- Maintenance and TCO: Trim provisioning, packing sets, accessibility and planned maintenance intervals.

Application summary table: line-based valve solutions

| Sector | Typical Line | Recommended Valve Types | Sealing Design | Material/Trim | Pressure Class* | Temperature Range* |

|---|---|---|---|---|---|---|

| Oil & Gas (Up/Mid) | Main transfer, pigging lines | Trunnion ball, slab gate, dual plate check | Metal-to-metal / soft seat | Carbon steel, stainless steel, Ni alloys | 150–900 | −46…+200 °C |

| Oil & Gas (Down) | Loading–unloading, manifolds | Trunnion ball, plug, globe (throttling) | Low-emission packing | Stainless steel, cryogenic grades | 150–600 | −196…+200 °C |

| Power | Feedwater, bypass, steam | Globe (throttling), gate, check | Metal-to-metal, graphite gaskets | Cr–Mo steels, stainless steels | 300–2500 | +150…+600 °C |

| Chemical | Reactor feed/solvents | Plug/ball, globe, diaphragm | PTFE/PFA linings, soft seats | Stainless steel, lined body/trim | 150–600 | −20…+220 °C |

* Values are typical and may vary depending on project data.

Tightness and emissions: the invisible side of performance

Valve solutions are not only about shut-off; they are also about controlling fugitive emissions. Low-emission packings, properly machined seats and correct torque settings directly support environmental targets and occupational safety. For throttling duties, multi-stage trims and noise/cavitation control accessories protect both equipment and the surrounding environment.

Actuator integration and automation

The correct actuator is selected based on required torque, stroke time, fail-safe mode and feedback needs. Pneumatic spring-return solutions stand out in ESD lines, while electric actuators offer precise positioning and energy efficiency. SIL and ATEX requirements make it mandatory to select hardware that matches the safety instrumented level of the system.

Materials and metallurgy: the basis of life cycle and reliability

In sour-service environments, hydrogen embrittlement risk is managed through appropriate materials, heat treatment and surface hardness. In chemical plants, solvent/acid-based corrosion is handled with lined bodies/trims, while in power plants, alloyed steels are preferred for shape stability at high temperature. In all cases, traceability (EN 10204) and NDT plans form the backbone of quality assurance.

Maintenance strategy: reducing total cost of ownership (TCO)

In planned maintenance, packing adjustment, seat/disc surface checks and actuator diagnostics are essential. Easily replaceable trims and standardised spare parts lists reduce downtime. Properly selected industrial valve solutions offer a longer service life that offsets initial investment differences in a short time.

EMS Valve’s project approach

EMS Valve analyses your sector-specific specifications (P&ID, pressure–temperature envelope, fluid chemistry) and proposes ready-to-implement valve solutions. Standard compliance, emission targets and automation requirements are combined in a single engineering package: technical offer, drawings, test plan and traceability documents are clear and transparent.

Conclusion and next step

The right valve solutions enhance safety, reduce downtime and increase operational efficiency in your oil & gas, power and chemical plants. Share your project data with us; our engineers will schedule a 15-minute technical review and prepare a fast, application-specific quotation tailored to your needs.

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.