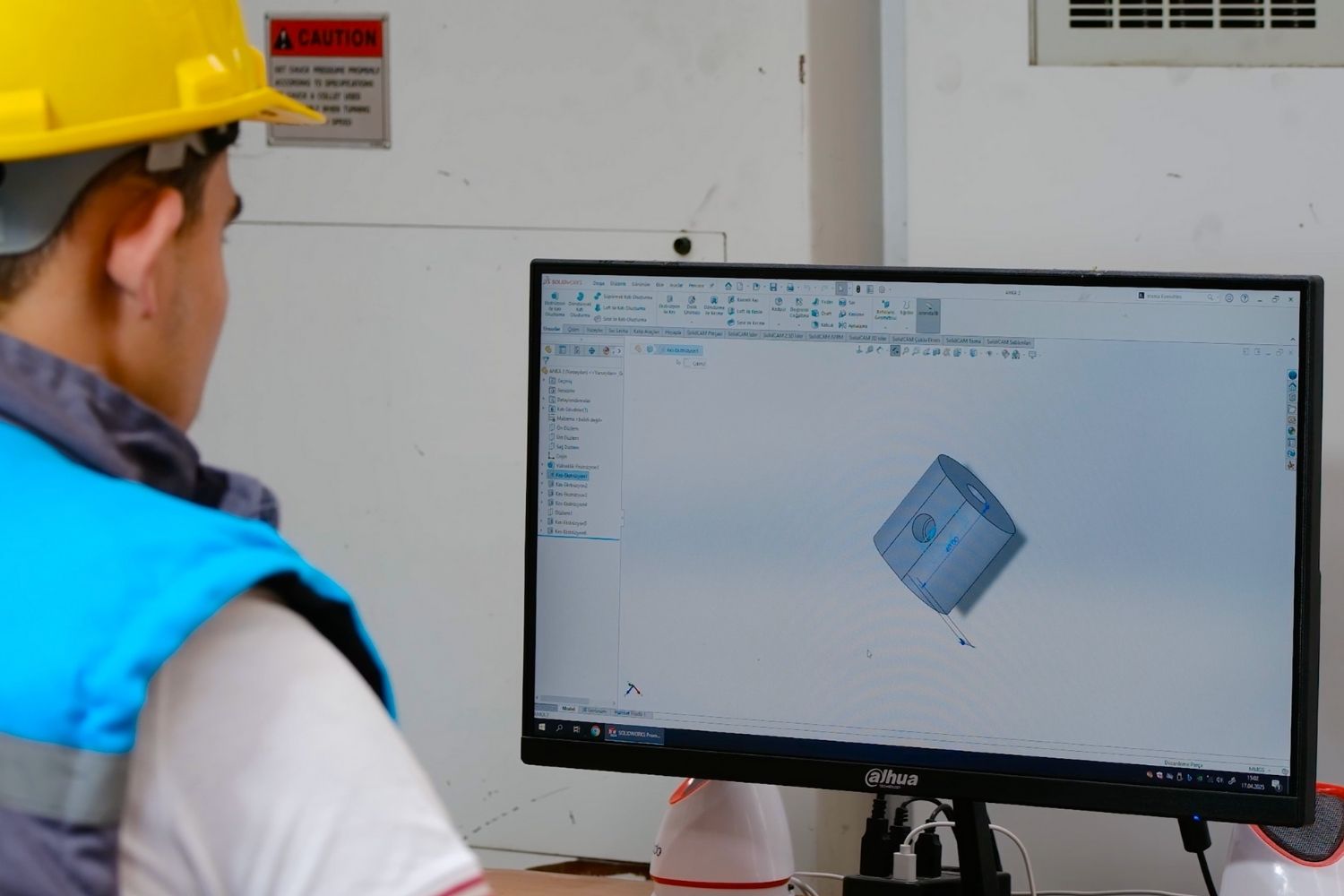

Trunnion Ball Valve (ANSI)

|

Nominal Size : |

1/2″-24″ |

|

Pressure Rating : |

150LB-300LB-600LB-900LB-1500LB |

|

Design Standards : |

API 600 |

|

Actuation : |

Lever operated, gear operated, pneumatic actuated, electric actuated, hydraulic actuated |

|

End Connections : |

Bw, Flanged-Rf/RTJ |

|

Materials : |

ASTM A105&A216-WCB&A352-CF8&A352-CF8M&A352-CF3&A352-CF3M |

The trunnion ball valve (ANSI) provides reliable flow control in oil & gas, chemical and general process lines thanks to its low torque requirement, high tightness and long service life. With EMS Valve’s engineering strength and disciplined testing procedures, we deliver fast, safe and cost-effective solutions for your projects.

40+ Years of Experience

We have been operating in the sector since 1979.

Manufacturer’s Guarantee

Fast delivery and competitive pricing with our guarantee.

High Quality

We ensure high-quality production to international standards.

What Is a Trunnion Ball Valve (ANSI)?

A trunnion ball valve is a type of ball valve in which the ball is supported on upper and lower trunnion pins, distributing line pressure evenly to the seats. This design provides low operating torque and stable tightness, especially in large diameters and high-pressure classes. With double block and bleed (DBB) options, it enhances line integrity and raises safety in both operation and maintenance areas.

Technical Features and Advantages

- Low torque – high tightness: Thanks to the trunnion-mounted design, actuator size is reduced and energy consumption decreases.

- DBB/DIB options: Double block and, where required, line/valve bleeding for safe isolation.

- Fire-safe design: In suitable configurations, provides fire safety in accordance with API 607 / ISO 10497.

- Fugitive emission control: Design options aligned with ISO 15848 requirements for fugitive emissions.

- Antistatic & blow-out proof stem: Protection against static electricity and prevention of stem blow-out.

- Wide body/seat range: “Soft seat” options such as EPDM, NBR, FKM, PTFE, RTFE, PEEK as well as metal-to-metal sealing alternatives.

Performance Highlights

- Long-life seating surfaces: Optimised seat loading minimises wear.

- Flow integrity: Full-bore design reduces pressure drop and, where pigging is applicable, facilitates line cleaning.

- Standardised accessories: ISO 5211 top flange with keyed stem interface enables fast and secure actuator integration.

Actuation, Automation and Accessories

The ISO 5211 top flange enables fast integration of manual gearboxes, pneumatic (single-acting / double-acting) and electric actuators. Limit switch boxes, solenoid valves, positioners, pressure regulators and air preparation units ensure full integration into SCADA/DCS systems. Emergency shut-down (ESD), on/off service, remote monitoring and SIL-focused solutions can be engineered as part of the package.

Application Areas and Performance

The trunnion ball valve delivers efficient and reliable performance in the following processes:

- Oil & gas transmission pipelines, piggable full-bore solutions

- Refinery & petrochemical plants, high-temperature and aggressive media

- Power plants, steam–condensate and auxiliary systems

- Water, wastewater & seawater with corrosion-resistant materials

- General process industries, solvent and chemical lines

Trunnion Ball Valve Price and Quotation Process

The price of a trunnion ball valve depends on the following parameters: size (NPS/DN), ASME class, body/seat material, DBB/DIB configuration and test scope. Once you share your project specification, EMS Valve engineers determine the most appropriate configuration and prepare a competitive, transparent and rapid quotation.

If you need low torque, high safety and long service life in large diameters, the trunnion ball valve (ANSI) is the right choice. Together with EMS Valve’s engineering team, we can define the most suitable trunnion ball valve configuration for your project. Request a quotation now so that we can optimise both performance and total cost of ownership.

Contact Form

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.