Industrial Valve Solutions for the Construction Industry

We deliver industrial valve solutions for the construction industry with 100% domestic manufacturing and quality compliant with international standards.

Construction Industry and Valve Solutions

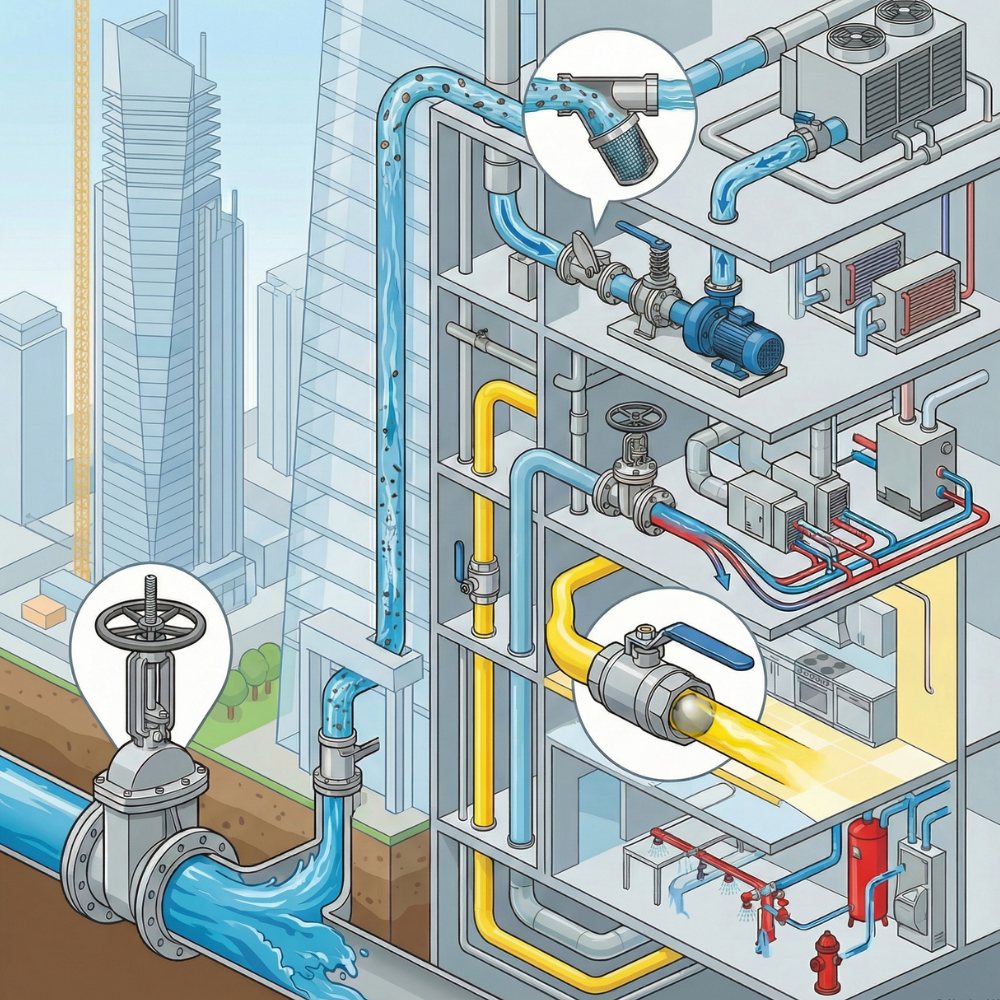

In construction-sector valve applications—from skyscrapers to infrastructure projects, and from heating–cooling lines to fire protection systems—we ensure uninterrupted flow safety backed by over 40 years of experience. Our durable valves, developed with 100% domestic manufacturing strength and designed to fully comply with your project’s technical requirements, extend the service life of structures while optimizing operating costs. Discover our products tested through modern engineering simulations.

The Importance of Flow Control and Safety in Modern Buildings

Today’s construction projects are evaluated not only by aesthetics but also by complex engineering infrastructures. High-rise buildings, industrial facilities, and large-scale campuses require flawless flow control mechanisms to transport water, steam, or gas safely. At this point, construction-sector valve systems play a critical role—from maintaining pressure balance to ensuring tight shut-off. At EMS Vana, inspired by our heritage, we move confidently toward the future by manufacturing these systems—often considered the “heart” of buildings—at the highest quality standards.

A high-quality valve system is critical to the sustainability of any construction project. Incorrectly selected or substandard products can increase maintenance costs over time and pose serious risks, such as flooding or failure to activate during a fire. By transferring our experience from the demanding conditions of the oil and gas industry to construction, we offer products that deliver maximum performance even under the harshest conditions. Safety and durability are the cornerstones of our manufacturing philosophy.

Core Valve Technologies Used in Construction Projects

In mechanical installations of construction and contracting projects, the most commonly used solutions include gate valves, globe valves, and ball valves. Gate valves, used primarily to fully open or close a line, are preferred in main pipelines due to their low pressure loss. Our ANSI- and DIN-compliant gate valves are available in both forged and cast options to match your project specifications precisely. Thanks to their superior sealing performance, they are safely used in building water distribution networks.

Where precise flow regulation is required, globe valves stand out. In heating, ventilation, and air conditioning (HVAC) systems, regulating the amount of water or steam is essential for energy efficiency. Our globe valves are designed using stress and deformation simulators, ensuring they retain their form and performance even under high pressure for many years. This technology significantly improves flow direction control and system balancing.

Preventing backflow is critical, particularly in pump stations and booster lines of multi-story buildings. Here, check valves ensure one-way flow, protecting pumps and piping from damage. Our swing and dual-plate models act as a safeguard for installations with their resistance to sudden pressure surges. In addition, our ball valves, known for rapid opening and closing, provide emergency response capability in fire lines and gas distribution systems, maximizing life and property safety.

Valve Types Used in the Construction Industry and Their Features

| Valve Type | Primary Function | Construction Application Area | EMS Vana Standard |

|---|---|---|---|

| Gate Valve | On / Off | Main Water Lines, Fire Circuits | ANSI, DIN |

| Globe Valve | Flow Regulation | HVAC, Boiler Rooms, Steam Lines | ANSI, DIN |

| Ball Valve | Fast Control / Tight Shut-Off | Natural Gas Lines, Apartment Inlets | ANSI, DIN (Trunnion/Floating) |

| Check Valve | Backflow Prevention | Pump Outlets, Booster Systems | Swing, Dual Plate |

| Strainers (Y-Type) | Debris Removal | Installation Inlets, Upstream of Sensitive Equipment | Forged Steel |

Engineering Excellence: Design and Testing Processes

What sets EMS Vana apart is our role not only as a manufacturer but also as an engineering solution partner. Our products are designed to match customer specifications and process duties precisely. Each construction project has unique pressure, temperature, and fluid requirements. Using 3D design software and integrated simulation tools, our engineers analyze material stress and deformation risks prior to production, preventing unexpected failures in the field.

Quality documentation is mandatory, especially for large-scale public and private construction projects. In our ISO 17025–accredited laboratory, visual, dimensional, and chemical analyses are conducted meticulously. Pressure tests are performed in accordance with API 6D or API 598 standards and, upon request, under third-party inspection. Through non-destructive testing procedures (radiographic, ultrasonic, etc.), we ensure the integrity of valves installed in foundations or hard-to-access areas.

Why Choose EMS Vana?

With a heritage dating back to 1979, we manufacture high-capacity solutions for the construction industry at our 15,000 m² production facility. We are not merely a supplier but a partner providing technical support at every stage of your project. Logistics advantages of domestic manufacturing and rapid spare-parts availability keep your construction sites running without interruption.

- 100% Domestic Manufacturing Strength: Fast and reliable delivery without import delays.

- Comprehensive Product Range: One-stop solutions from gate, globe, ball, and check valves to Y-type strainers.

- International Certification: Full compliance with ANSI, ASME, API, and PED requirements.

- Expert Team: Precise testing and inspection conducted by ISO 9712–qualified personnel.

- Customer-Centric Approach: Flexible manufacturing and custom design tailored to client specifications.

At EMS Vana, we are at your service with long-lasting, certified construction industry valve solutions that add value to your projects. By combining over 40 years of experience with modern technology, we ensure your structures operate safely and reliably. If you are seeking a solution partner that never compromises on quality, delivers on time, and provides strong after-sales support, contact our expert team. Let us build the future together.

Contact Us Now

Reach out to our expert team today for tailored valve solutions for your projects.