EMS

FROM OUR FOUNDER

TO YOU...

Today, inspired by our strong heritage, we move forward with confidence and carry the responsibility of producing more—for our country and the world.

Just as in the past, EMS Valve will continue to grow and evolve alongside you, our valued stakeholders, today and in the future.

EMS

40 Years of Production

EXPERIENCE

100% LOCAL PRODUCTION

In the field of valve design, manufacturing, and supply, EMS Valve is a leading group serving the oil and gas, power generation, refinery, chemical, and other industrial sectors.

Today, EMS Valve’s strong market position is built on decades of high-quality manufacturing tradition, a highly skilled team, and a commitment to providing the best solutions for its customers—strengthened further by flexible product and service presentation strategies that foster lasting trust.

EMS

High

Engineering

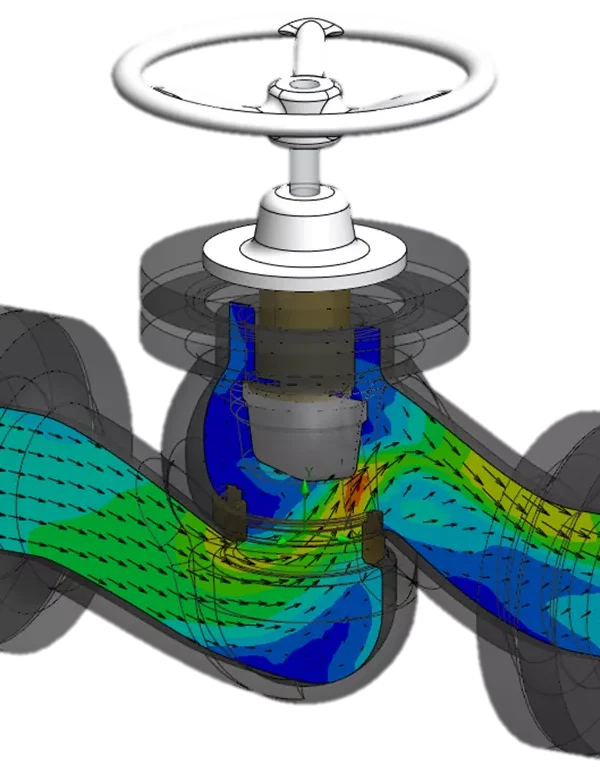

Our engineers work with the aid of integrated 3D design software, supported by stress and deformation simulators.

The simulation of every structural element—controlling material stress and strain, reaction forces, and residual stresses—serves as the starting point of our design process.

Testing and Controls

Positive Material Identification (PMI) is carried out in an ISO 17025 accredited laboratory, including visual and dimensional inspections, chemical composition analysis, tensile, hardness, and impact tests, as well as metallographic examinations.

Non-destructive testing (NDT) procedures include visual and dimensional process inspections per MSS SP-55; dye penetrant, magnetic particle, ultrasonic and radiographic testing according to ASME codes; acoustic emission diagnostics; and vacuum leak tests for fugitive emissions. All tests are performed by personnel qualified under ISO 9712.

Certificates & Approvals

PED CE

ISO 9001

ISO 14001